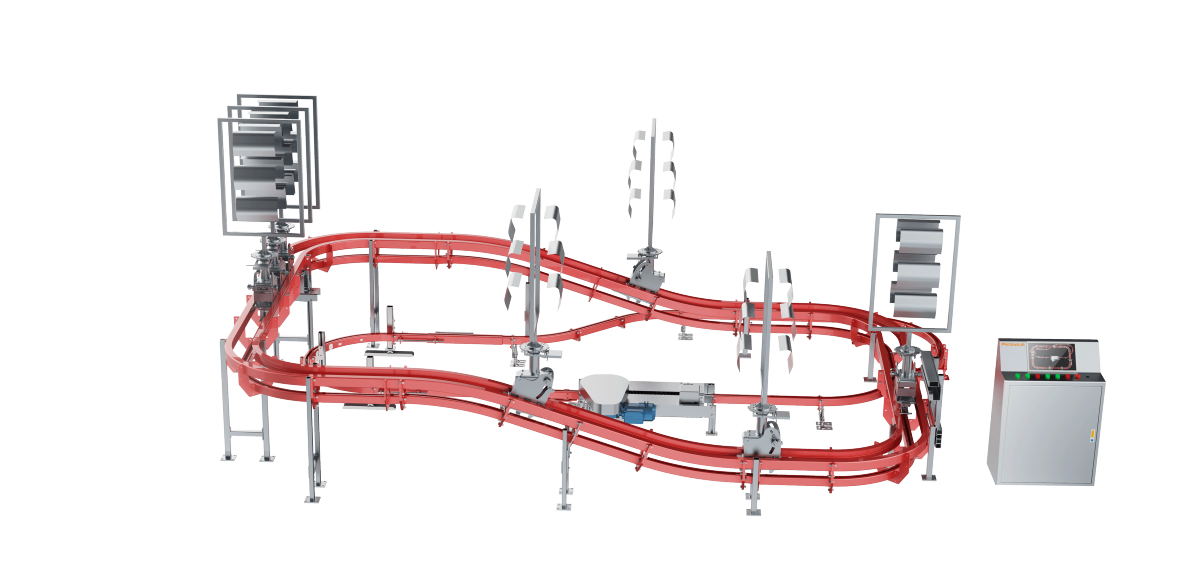

智能悬挂输送系统

SMART RAIL CONVOYOR SYSTEM

系统理念

DESIGN PHILOSOPHY

模块化家族设计

Modular Family

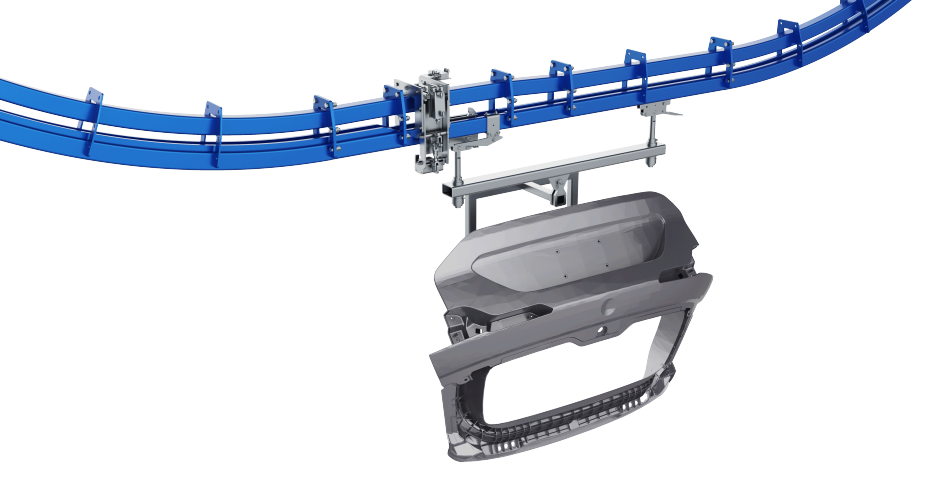

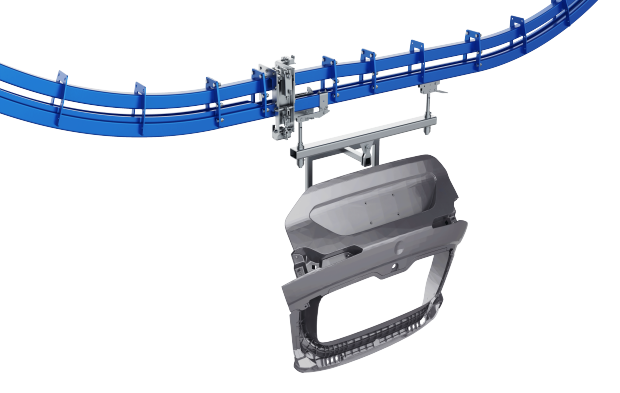

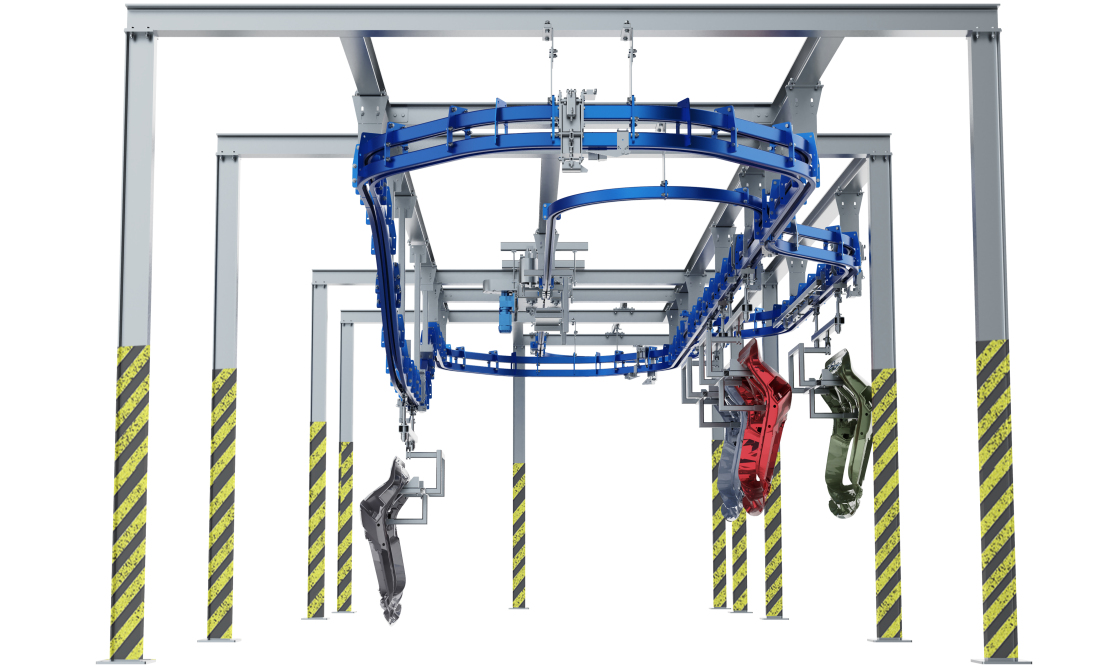

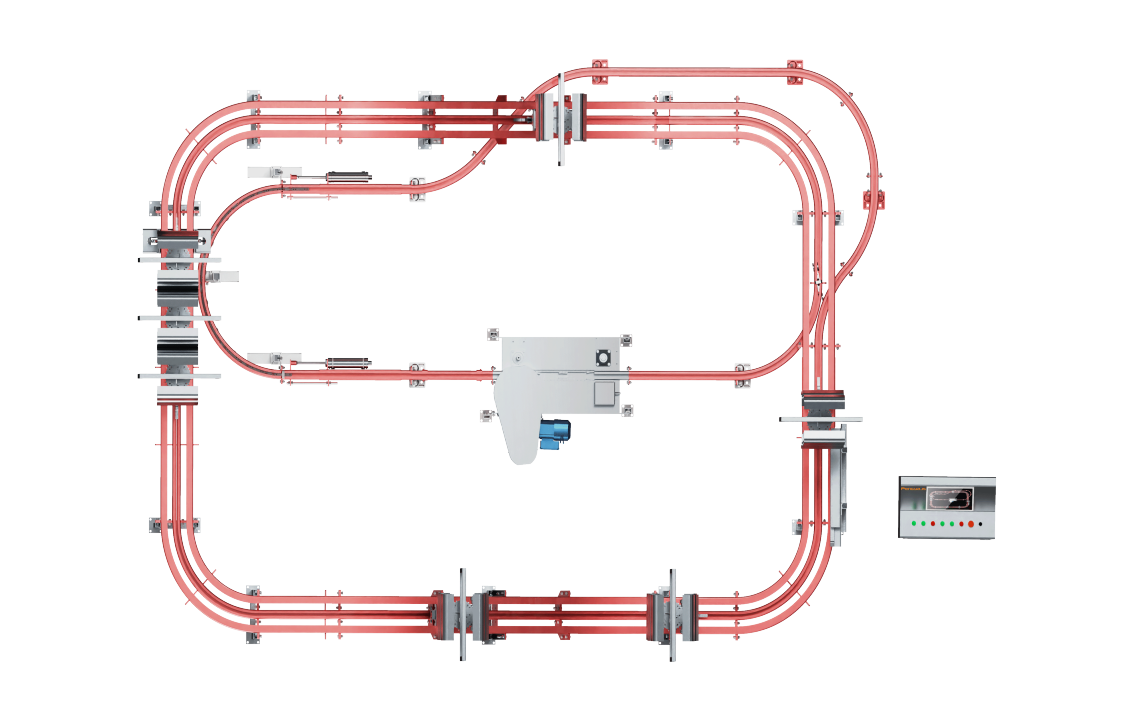

悬挂型积放式输送

Suspended Accumulating Convoyor

2大悬挂输送体系

2 SUSPENDED CONVOYOR SYSTEM

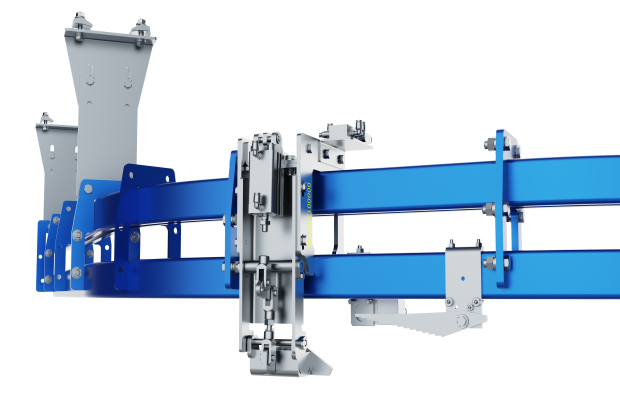

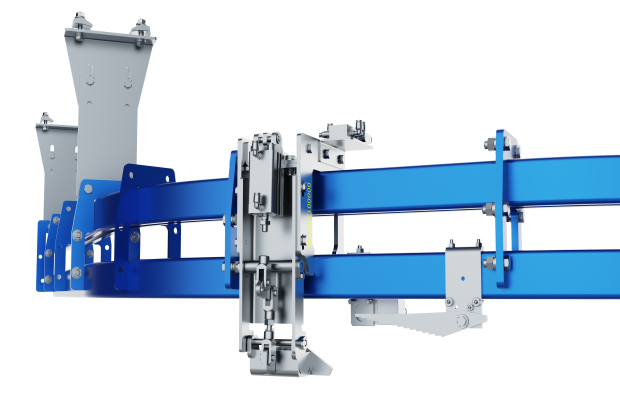

悬挂型积放式输送

Suspended Accumulating Convoyor

全新一代高度可靠的重型地板输送机,旨在满足客户处理更大,

更重和不平衡夹具的全面需求,提升生产能力和弹性。

4个水平导向轴承和完全可调的轨道部分可实现高精度的导向。

由于限制使用驱动单元和传感器,因此与传统的橇式系统或

辊道输送机相比,需要最低限度的控制系统。

A new generation of highly reliable heavy floor conveyors, designed to meet the

needs of customers with larger handling capacity. More heavy and unbalanced

fixture overall demand, improve production capacity and flexibility. Four horizontal

guide bearings and fully adjustable track section can achieve high precision guidance.

Due to restrictions on the use of drive units and sensors, the traditional skid mounted

system or Compared with roller conveyor, minimum control system is required.

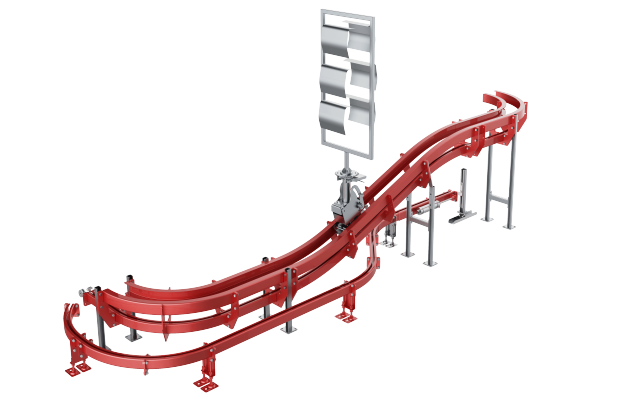

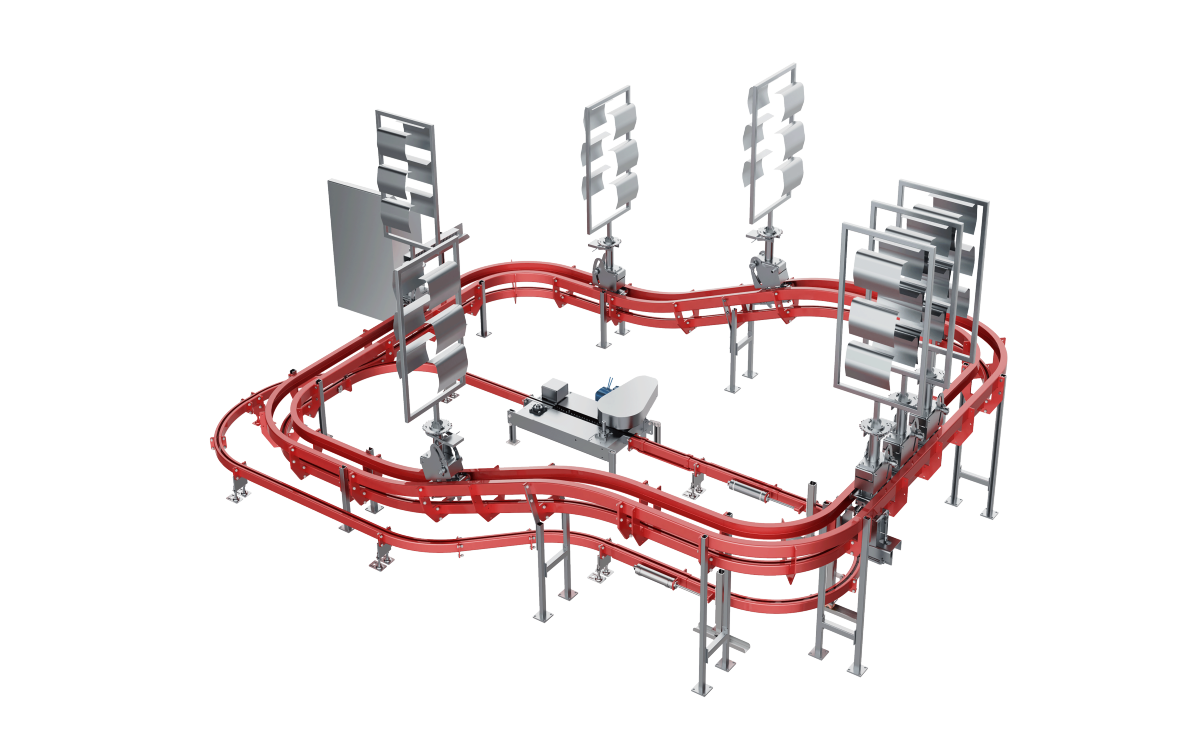

我们提供范围广泛的悬挂积放输送系统,

从简单的手动系统到再到复杂的PLC系统。

现已开发了6种不同的型号,从重量几克到10000千克不等。

所有系统都是针对表面精加工行业的极端情况而首先开发的,

并且旨在以最小的维护量实现高效率的运行。

We offer a wide range of suspended stacking and conveying systems,

From simple manual system to complex PLC system.Six different models

have been developed, ranging from a few grams to 10000 kilograms.

All the systems were first developed for the extreme conditions of the

surface finishing industry,and it aims to achieve efficient operation with

minimum maintenance.

鹏亚提供高度灵活的家族化模块设计,从原生层面为系统提供极高的通用性,拓展性,既能适应当前的生产场景,又为后续产线的灵活调整预留了巨大的弹性。

Pengya provides highly flexible family module design, which provides high universality and expansibility for the system from the original level. It can not only adapt to the current production scenario, but also reserve great flexibility for the flexible adjustment of subsequent production lines.

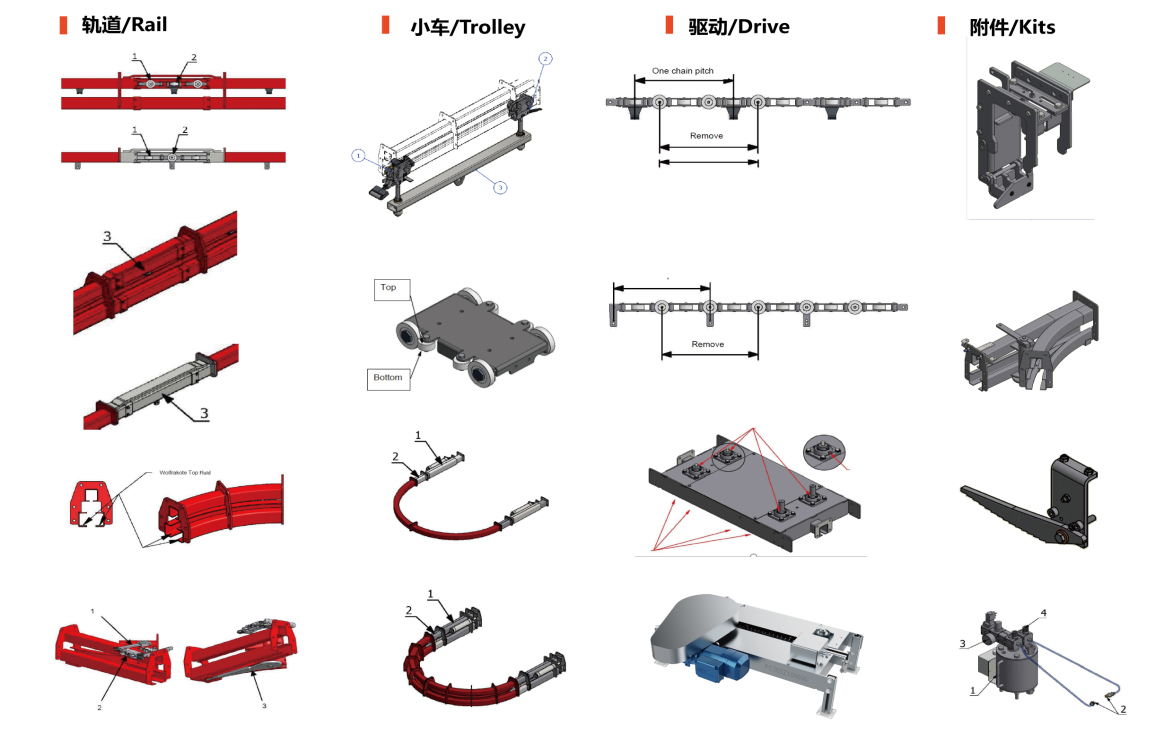

模块化家族设计体系

MODULAR FAMILY

系统设计,

模块组合

Modular System

悬挂型积放式输送

多种场景,

灵活拓展

Modular Flexible

模块设计,

系统延展

Modular Design

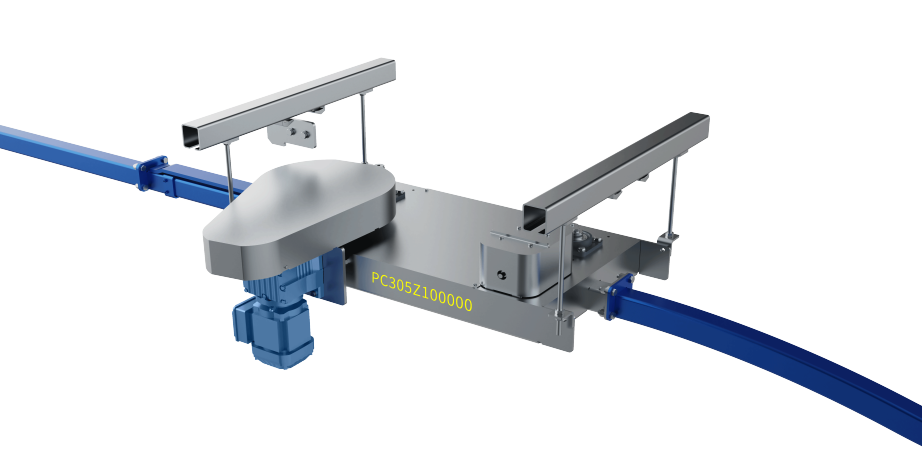

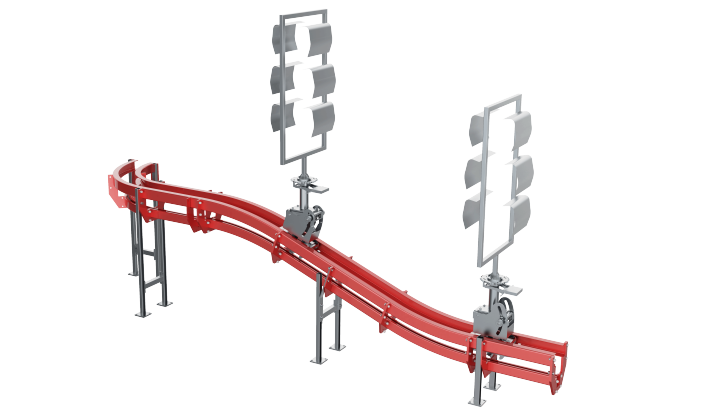

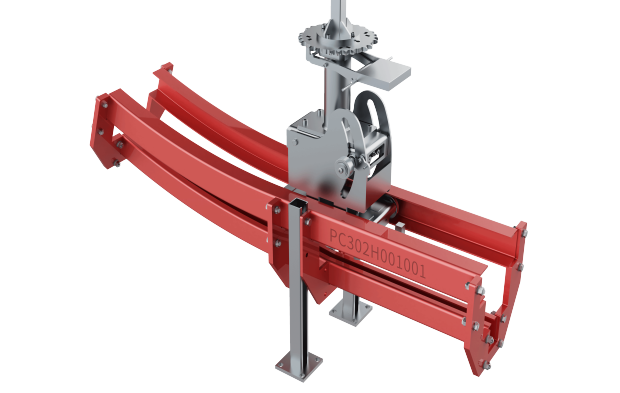

为保证系统成本,因此小车的设计非常注重系统内运行平顺。

无需使用推车机,即可实现小车在不同线路间的切换。

The leading edge PENGYA trolley- and accumulation stop

design is the safeguard for instant and extremely reliable

separation of wagons in theaccumulating zones.

领先的鹏亚小车和停止器的设计,为小车组在积放区快速可靠

的车链分离提供了保障。小车与输送机链条之间无摩擦式分离,

在积放时实现有效降噪。

The system handles accumulation noiseless with non-friction

disengagementof the trolleys from the conveyor chain drive.

在配置输送机布局时,通过采用模块化的构件,为系统提供了高

标准的灵活性和自由度。除此之外,高精度的鹏亚高端组件和质

量检测确保了全球客户都能在严苛环境下完全放心地运行。

Through the use of modular components, the system is the

paramountstandard of flexibility and liberty when it comes to

configuring conveyorlayouts. On top of that the rigorous and

renowned PENGYA high-endcomponents and quality testing,

ensures that clients worldwide can runour systems in harsh

environments with total confidence.

鹏亚提供高度灵活的积放式输送机,其承载能力可达500公斤。

通过简单可靠的小车组积放,能够实现缓存区内45°或90°或

直线排列放置。

To ensure low system costs, the system has a minimal need

for transferunits, as it is designed with a highly smooth trolley

transfer from oneconveyor circuit to another.

节能环保,

超低能耗

Eifficiency

SUSPENDED ACCUMULATING CONVOYOR SYSTEM

四大优势,引领行业

Modular Advantages

系统设计,

模块组合

Modular System

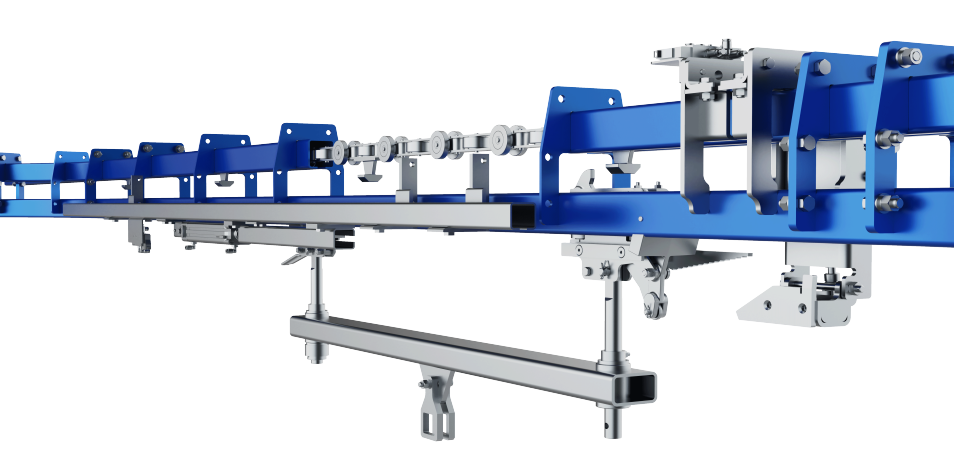

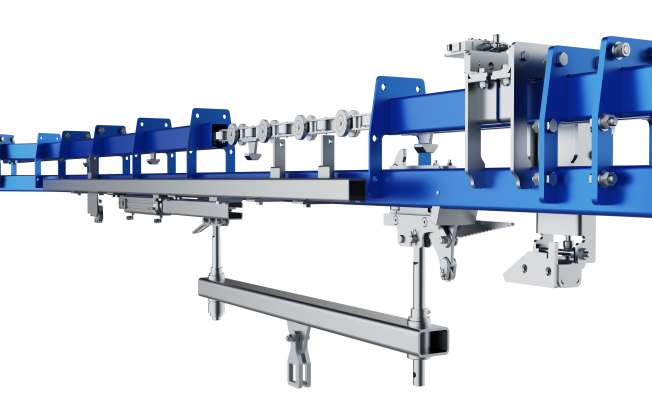

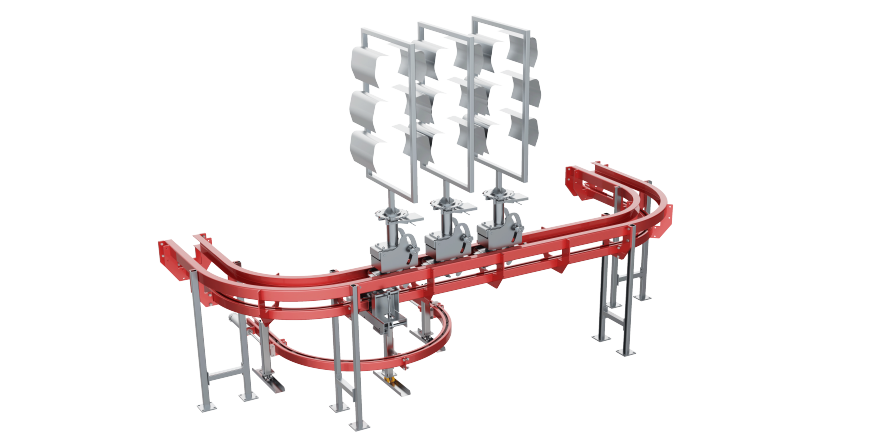

地轨型积放式输送

多种场景,

灵活拓展

Modular Flexible

模块设计,

系统延展

Modular Design

车组带有的四个到六个水平导向轮可确保导向精度的提高。

这意味着:更高的生产质量更高的产出效率。

Furthermore, the four to sixhorizontal guide wheels allow

forincreased guidance accuracy.This means:higher production

quality and Increased output efficiency.

输送系统关键部件维护简单,只需要极少的维护和用户培训,

根据客户需求,此地面输送系统的单车负荷可改为150公斤。

Easy access to the vital parts of the conveyor system, only a

minimum of maintenance and user training is required.

On customer request this floor conveyor system can be

modified to a 150 kg load capacity.

紧凑的设计使整体高度得以降低,可减少工艺区域的空间占用

相对于传统的输送系统,如皮带式和滚筒式输送机,此输送机

的解决方案更节省空间。

The compact design allows a low overall height and takes up

less space in the process areas.

地面传送系统凭借其对车组的稳定双侧支撑,为输送一些大件、

摇晃不稳的夹具或工件提供了十分坚实的基础。

T floorconveyor provides a very solid base for even very large

and unbalanced jigs / product carriers.

节能环保,

超低能耗

Eifficiency

RAIL ACCUMULATING CONVOYOR SYSTEM

四大优势,引领行业

Modular Advantages

智能控制系统

Our conveyor system is only the "heart" of the built-in electrical control system.

The demand for system security and various system functions has grown rapidly in the past few years.

For more than 10 years, our internal control systems division has produced and built control and automation systems for conveyors. Pengya's hardware and software functions are strongly integrated - high quality integration, no unnecessary interfaces.

We can provide:

· Connection with customer ERP system

· database coupling for order management

· Filing process data into PLC control system

Our software and control solutions are designed based on a common control concept from field to manufacturing execution system (MES). The control and software products we use have modular designs that can be used to develop

and implement custom solutions.

Simulation and visualization

Through system simulation and visualization, we have outlined the material flow available to customers.The larger the conveyor system, the more complex it is, the more important it is to have an overview of all process steps and the status of the project to be addressed.The efficiency of the process ensures productivity and gives our customers a competitive advantage.

INTELLIGENT CONTROL SYSTEM

场景驱动,行业定制

SCENARIOS DRIVEN

我们的输送机系统仅是内置电气控制系统的“心脏”。

系统安全和各种系统功能的需求在过去几年中迅速增长。

因此,用于我们的智能输送机解决方案的控制系统变得越来越复杂。

10多年来,我们的内部控制系统部门为输送机生产和建造了控制和自动化系统。

鹏亚的硬件和软件功能强大地结合在一起-集成质量高,没有不必要的接口。

我们可以提供:

与客户ERP系统的连接

用于订单管理的数据库耦合

将过程数据归档到PLC控制系统

我们的软件和控制解决方案是根据从现场到制造执行系统(MES)的通用控制概念设计的。

我们使用的控制和软件产品具有模块化设计,可用于开发和实施定制解决方案。

模拟和可视化

通过系统模拟和可视化,我们概述了可供客户使用的物料流。输送机系统越大,越复杂,

所有过程步骤的概览以及要处理的项目的状态就越重要。

流程的效率可确保生产率,并为我们的客户带来竞争优势。

智能悬挂输送系统