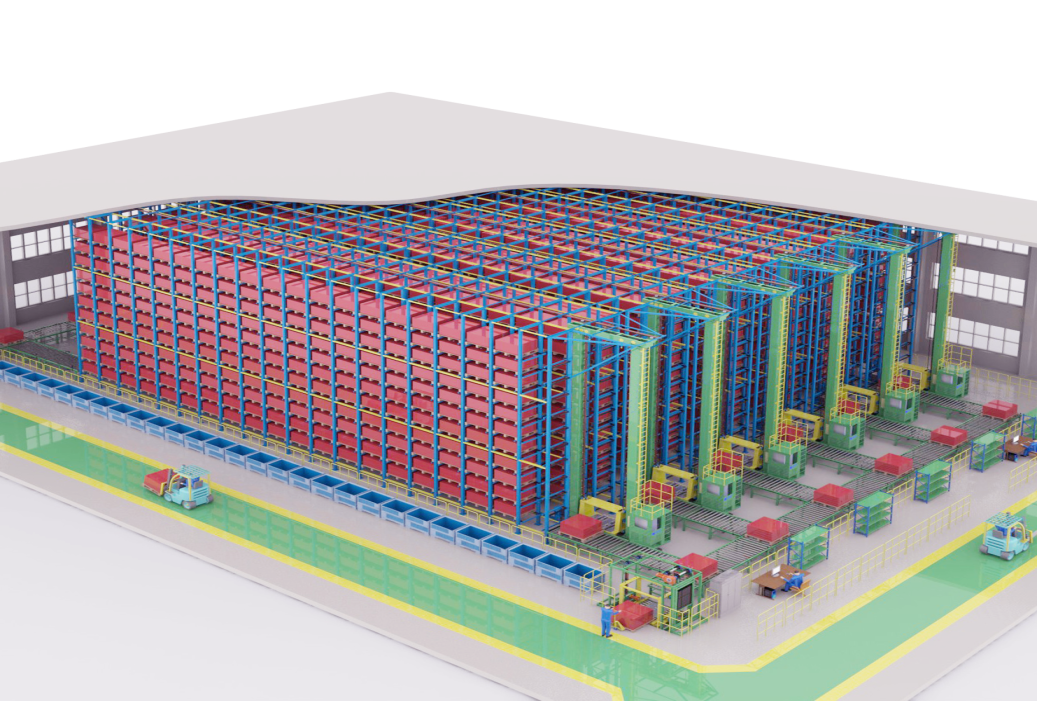

智能仓储系统

SMART STORAGE LIFTING SYSTEM

系统理念

DESIGN PHILOSOPHY

模块化家族设计

Modular Family

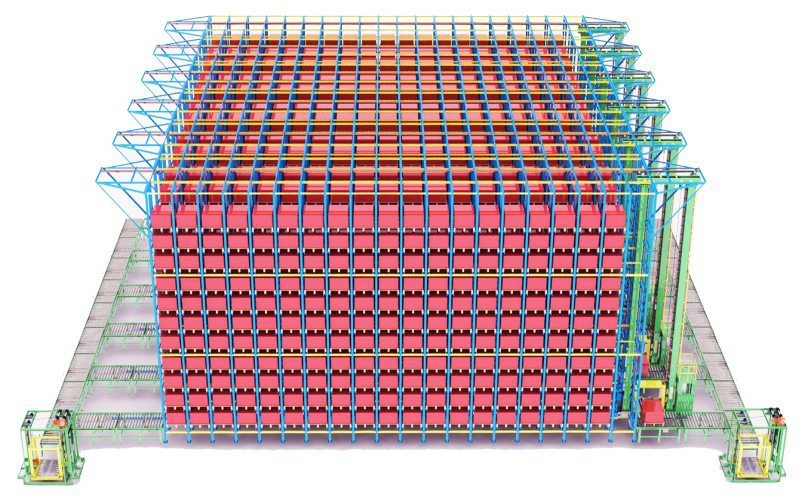

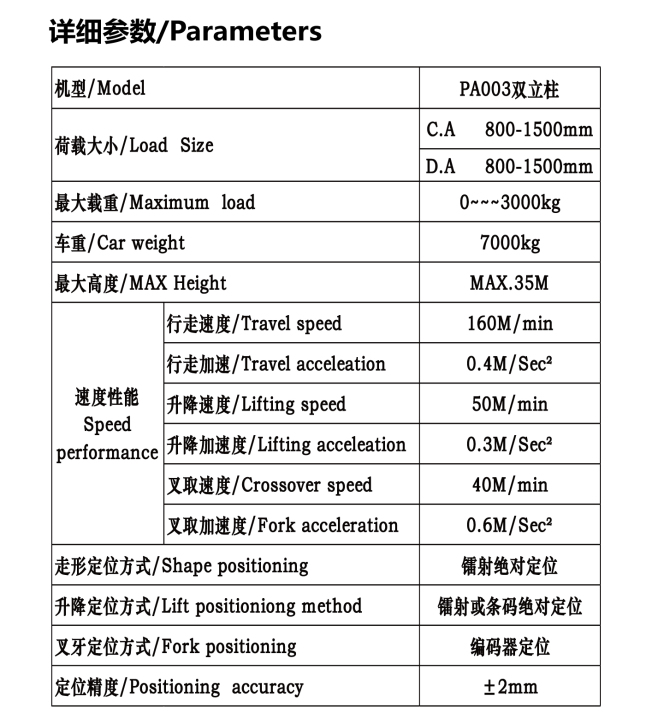

双立柱堆垛系统/

Duo-rail Storage Lifting System

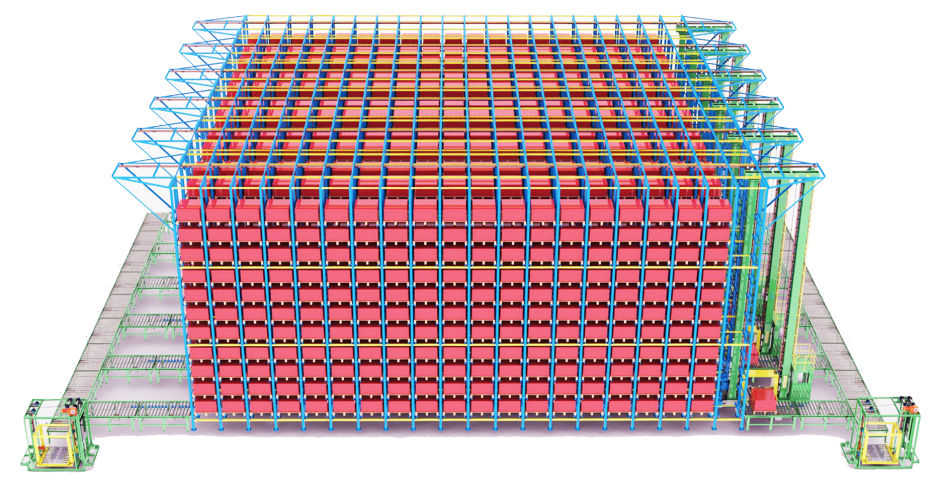

2大仓储搬运体系

2 STORAGE LIFTING SYSTEM

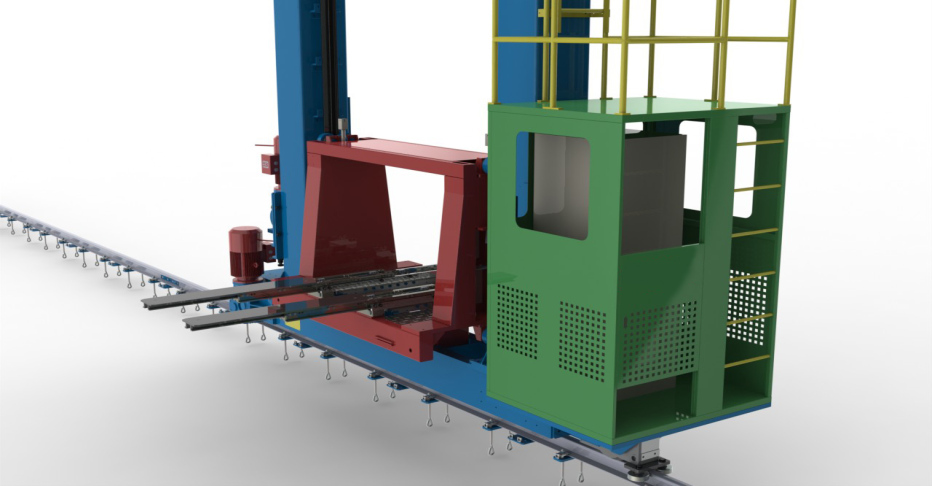

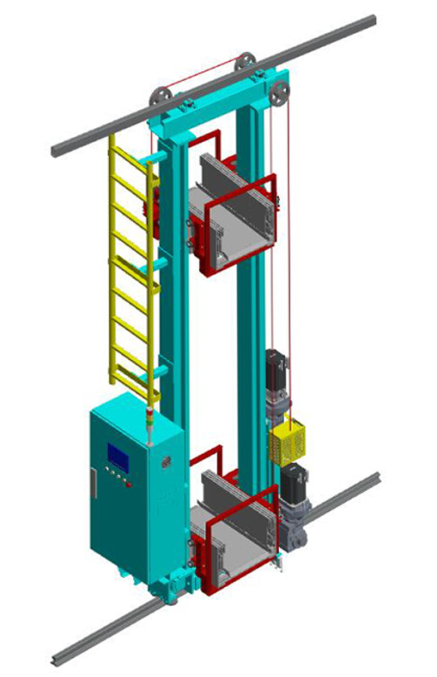

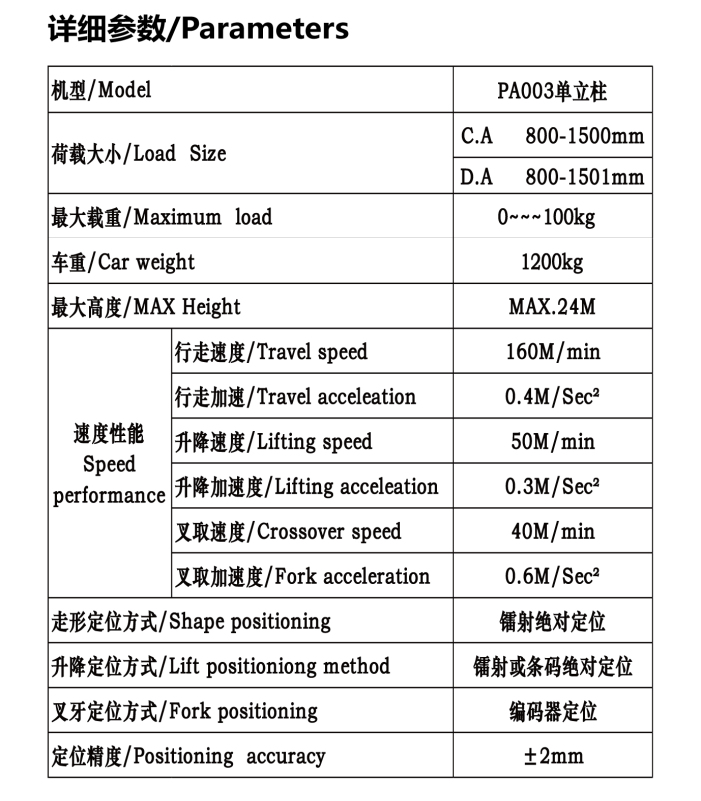

单立柱堆垛系统/

Mono-rail Storage Lifting System

全新一代高度可靠的单立柱堆垛机,旨在满足客户处理更多变,

更灵活和更紧凑的仓储需求,最大高度24米, 最大载重量1500千克。

特制水平导向轴承和完全可调的轨道部分可实现高精度的导向。

由于限制使用驱动单元和传感器,因此与传统的单立柱堆垛机相比,

需要最低限度的控制系统。

The new generation of highly reliable single column stacker is designed to meet

customers' needs for handling more changes, More flexible and more compact

storage requirements, maxium height 35meters, maxium load up to 1500 kilograms.

The special horizontal guide bearing and fully adjustable track part can realize

high precision guidance.Due to the limited use of drive units and sensors, compared

with the traditional single column stacker, only minimum control system is required.

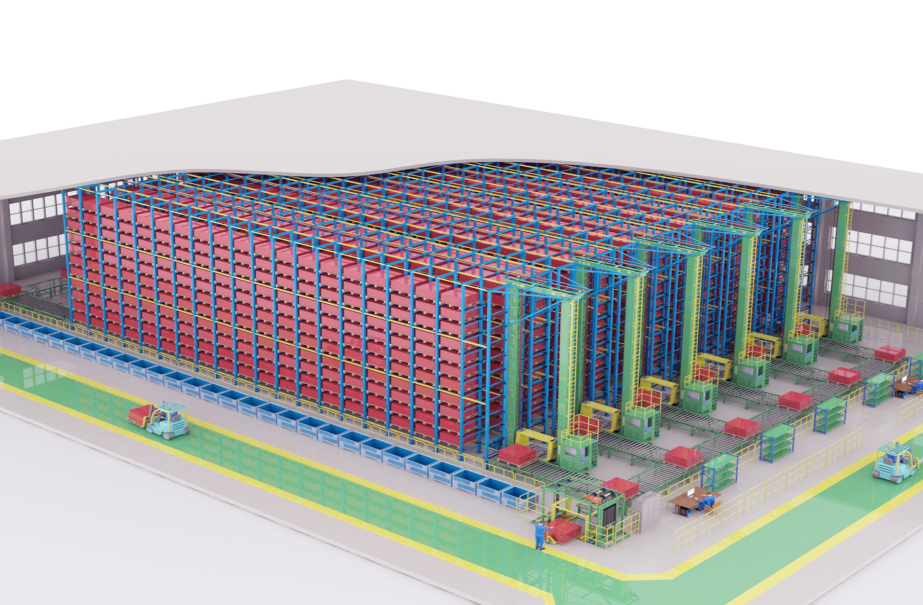

我们提供范围广泛的仓储搬运系统,从适合小型仓储场景的

系统到大型立体仓储场景的系统。现已开发了多种不同的型号,

最大高度35米, 最大载重量3000千克。

所有系统都是针对仓储行业的多样情况而首先开发的,

并且旨在以最小的维护量实现高效率的运行。

We offer We offer a wide range of warehousing and handling systems,

From the system suitable for small-scale storage scene to large-scale three-

dimensional storage scene system.Many different models have been developed, maxium height 35meters, maxium load up to 3000 kilograms.

All the systems are first developed for the diversity of the warehousing industry,and it aims to achieve efficient operation with minimum maintenance.

鹏亚提供高度灵活的家族化模块设计,从原生层面为系统提供极高的通用性,拓展性,既能适应当前的生产场景,又为后续产线的灵活调整预留了巨大的弹性。

Pengya provides highly flexible family module design, which provides high universality and expansibility for the system from the original level. It can not only adapt to the current production scenario, but also reserve great flexibility for the flexible adjustment of subsequent production lines.

模块化家族设计体系

MODULAR FAMILY

双立柱堆垛系统

Duo-rail Storage Lifting System

地轨型积放式输送

RAIL ACCUMULATING CONVOYOR SYSTEM

智能控制系统

Our conveyor system is only the "heart" of the built-in electrical control system.

The demand for system security and various system functions has grown rapidly in the past few years.

For more than 10 years, our internal control systems division has produced and built control and automation systems for conveyors. Pengya's hardware and software functions are strongly integrated - high quality integration, no unnecessary interfaces.

We can provide:

· Connection with customer ERP system

· database coupling for order management

· Filing process data into PLC control system

Our software and control solutions are designed based on a common control concept from field to manufacturing execution system (MES). The control and software products we use have modular designs that can be used to develop

and implement custom solutions.

Simulation and visualization

Through system simulation and visualization, we have outlined the material flow available to customers.The larger the conveyor system, the more complex it is, the more important it is to have an overview of all process steps and the status of the project to be addressed.The efficiency of the process ensures productivity and gives our customers a competitive advantage.

INTELLIGENT CONTROL SYSTEM

场景驱动,行业定制

SCENARIOS DRIVEN

我们的输送机系统仅是内置电气控制系统的“心脏”。

系统安全和各种系统功能的需求在过去几年中迅速增长。

因此,用于我们的智能输送机解决方案的控制系统变得越来越复杂。

10多年来,我们的内部控制系统部门为输送机生产和建造了控制和自动化系统。

鹏亚的硬件和软件功能强大地结合在一起-集成质量高,没有不必要的接口。

我们可以提供:

与客户ERP系统的连接

用于订单管理的数据库耦合

将过程数据归档到PLC控制系统

我们的软件和控制解决方案是根据从现场到制造执行系统(MES)的通用控制概念设计的。

我们使用的控制和软件产品具有模块化设计,可用于开发和实施定制解决方案。

模拟和可视化

通过系统模拟和可视化,我们概述了可供客户使用的物料流。输送机系统越大,越复杂,

所有过程步骤的概览以及要处理的项目的状态就越重要。

流程的效率可确保生产率,并为我们的客户带来竞争优势。

智能仓储系统